How to recycle plastic with enzymes

On an overcast spring morning in 2012, Federica Bertocchini was tending to her honeybees close to where she lived in Santander, on Spain’s picturesque northern coast. One of the honeycombs “was plagued with worms,” says the amateur apiarist, referring to the pesky larvae of wax moths that have a voracious — and destructive — appetite.

Bertocchini picked out the worms, placed them in a plastic bag, and carried on with her beekeeping chores. When she retrieved the bag a few hours later, she noticed something strange: It was full of tiny holes.

The scientist’s interest was piqued. Had the hungry worms simply chewed up the plastic, or had they changed its chemical makeup too? Quick tests in her lab confirmed, surprisingly, the latter: Something in the worms’ saliva had degraded the plastic. “From that point, the research started,” says Bertocchini, a developmental biologist formerly with the Spanish National Research Council.

She is now the cofounder of Plasticentropy — one of the numerous startups and research groups that have sprouted in recent years seeking bio-inspired means to recycle plastic. This biological recycling, as it’s called, could offer more effective and environmentally friendly alternatives to some of today’s problem-riddled recycling methods.

The effort has scientists scouring landfills, auto wrecking yards and other sites teeming with plastic pollution in search of organisms that might be able to break down plastic into its component pieces. By taking these microbes and enhancing their polymer-munching abilities in the lab, scientists hope to find an efficient way of reclaiming the building blocks of plastics. They would then use these subunits to manufacture new materials, thus creating an “infinite recycling” loop.

It’s early days, and finding enzymes fit for the task is just a first step. But biological recycling could be a valuable tool for fighting the ever-growing plastics problem.

“There are groups all over the world working on this — hundreds of groups, thousands of scientists — it’s really quite amazing,” says structural biologist John McGeehan, a consultant in plastics deconstruction who specializes in the discovery and engineering of enzymes for plastic recycling.

Recycling woes

These efforts could not come soon enough. Ever since plastics manufacturing began in earnest in the 1950s, production has soared. Estimates suggest that we make close to 460 million tons of plastic annually, equivalent to the weight of roughly 2.3 million blue whales.

Unfortunately, most of that plastic ends up burned, buried in landfills or dumped in the environment. It’s no wonder that plastic has penetrated every corner of our planet — from the deep oceans to both poles, it even comes down in the rain. It’s also in our bodies, with traces reported in placentas, breast milkand human blood; the use and disposal of plastics has been linked with several health and environmental issues.

Despite these problems, demand remains unabated, with production forecast to hit more than 1,000 million tons by 2050. That’s largely because plastics are hard to substitute — the material is a manufacturer’s delight: lightweight and easy to shape, with near-endless possibilities of properties it can be imbued with.

Given that replacing all plastics isn’t realistic, a next-best option is to make less virgin material from fossil fuels and to recapture more of what already exists. In other words, raise global plastic recycling rates from their present, dismal figure of roughly 9 percent.

The reasons behind that low rate are plentiful: Plastic is tough to break down; it can absorb harmful chemicals in the recycling process; and there are thousands of plastic types, each with its own composition, chemical additives and colorants. Many of these types cannot be recycled together.

“We have this major plastics circularity problem,” says Johan Kers, a synthetic biologist and cofounder of the Oregon-based enzymatic recycling company Birch Biosciences. “We can recycle aluminum; we can recycle paper; but we cannot, to save our lives, do a good job of recycling plastic.”

Nature offers a blueprint

Biological recycling could put a dent in the plastics problem. It involves using enzymes — the workhorses of biochemistry that speed up reactions — to break down plastic polymers into their subunits, called monomers. These monomers can then be used to make new plastics.

“The nice thing about enzymes is you get the building blocks back,” says McGeehan. “That’s potentially an infinite process, so it’s really attractive.”

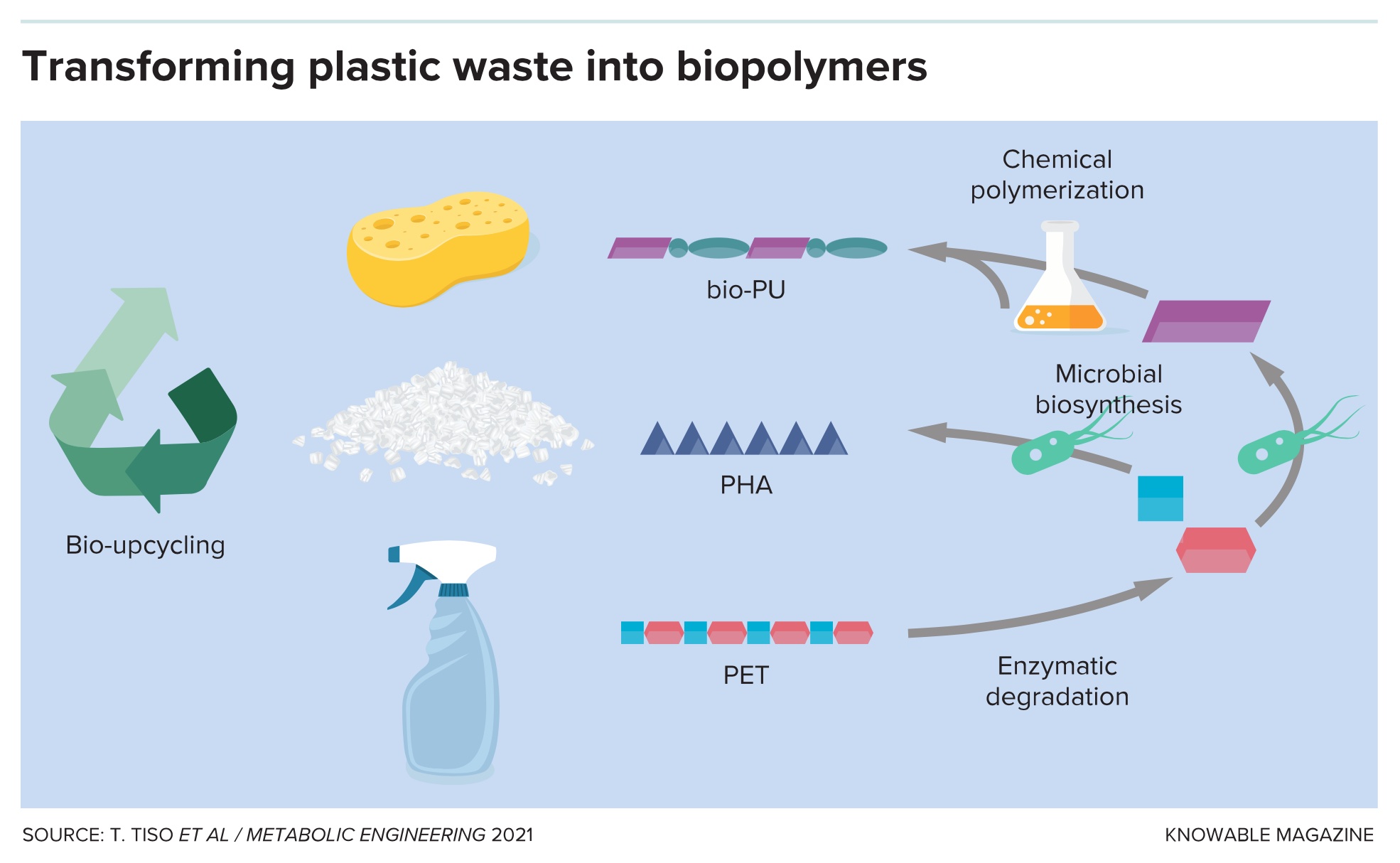

In a small-scale demonstration, researchers cut up a film of polyethylene terephthalate (PET) — a polymer commonly used in spray bottles and beverage containers — and used an engineered version of an enzyme found in a compost pile to breakdown the PET into its subunits (bottom). Some of those subunits were fed to another microbe that can make either the biopolymer PHA (middle) or an intermediate building block (purple). With some chemistry, that intermediate can be used to make another biopolymer, bioPU (top). The process is not yet entirely free of fossil fuel-based chemicals, but is a step toward harnessing plastic waste for new uses.

This approach could turn used plastics into a valuable resource, instead of a source of waste, says Ting Xu, a polymer scientist at the University of California, Berkeley, who cowrote an overview of biological-synthetic hybrid materials in the 2013 Annual Review of Physical Chemistry.

Research on plastic-eating enzymes goes back to at least the 1970s, but the field was reinvigorated in 2016, when a team of Japanese scientists published a landmark paper in Science describing a new strain of plastic-eating bacteria. Led by microbiologist Kohei Oda at the Kyoto Institute of Technology, the team found that the microbe, called Ideonella sakaiensis 201-F6, uses PET plastic — a polyester widely used in beverage bottles and fibers — as its major energy and food source.

The researchers came across the microbe in some scooped-up sediment when they were painstakingly shifting through 250 environmental samples they had collected from a bottle-recycling factory just outside of Osaka. Further testing revealed that I. sakaiensis could almost fully break down PET within six weeks.

Since then, scientists have discovered plastic-eating microbes at various sites around the world, including a compost heap at a cemetery in Leipzig, Germany; a waste disposal site in Pakistan’s capital, Islamabad; and weathered debris washed up on two beaches in Chania, Greece. A large-scale analysis of more than 200 million genes found in free-floating DNA in environments including the oceans, Arctic tundra topsoil, savannas and various forests turned up 30,000 different enzymes with plastic-degrading potential, a team reported in 2021.

Discovering enzymes, however, is only the first step. While many of the ones now under study are quick-acting and function well under mild conditions, scientists typically have to tweak them to perform better. For example, McGeehan, along with colleagues at the National Renewable Energy Laboratory in Colorado and elsewhere, engineered two enzymes responsible for the plastic-eating abilities of I. sakaiensis to dial up their performance and then linked them, creating an enzyme cocktail that can break down PET six times quicker than previously possible.

Scientists are also using artificial intelligence to dial up desirable attributes in the enzymes that depolymerize plastics quicker, are less picky about target substrates, and can withstand a wider range of temperatures.

Early data suggest that biological recycling could have a smaller carbon footprintthan making plastics anew. For example, using enzymes to break down PET to get one of its monomers, terephthalic acid (TPA), cut greenhouse gas emissions by as much as 43 percent compared with making TPA from scratch, according to a 2021 estimate.

Good targets for enzymes

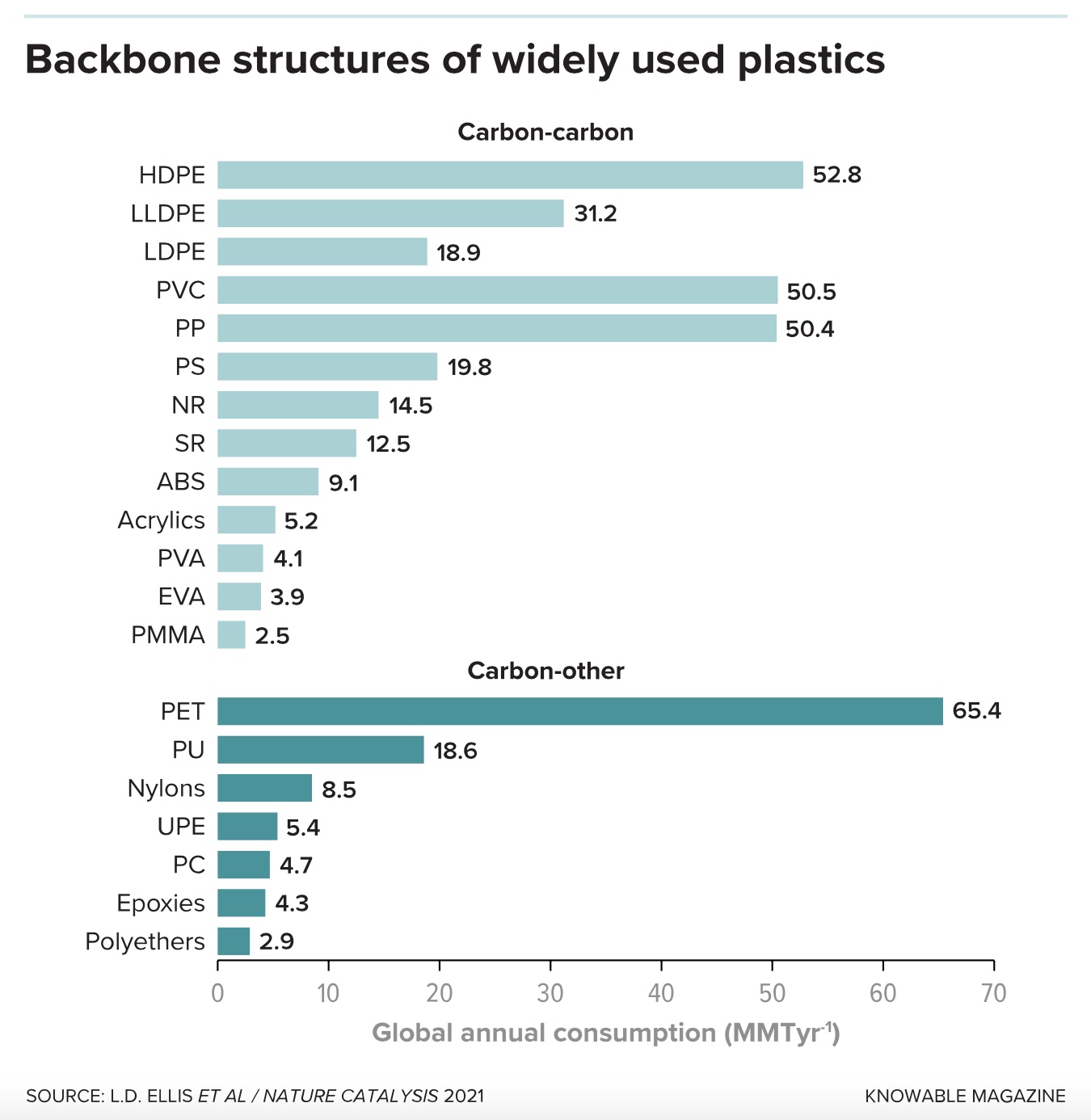

Of course, PET is just one of many kinds of plastic — they are generally divided into seven or more classes, depending on factors like their chemical structure. On one end of the scale sit plastics with mixed-carbon backbones — polymers with a central spine comprising carbon interlaced with other atoms such as oxygen and nitrogen. For now, these plastics are most suited to biological recycling largely because the enzymes available can chew through the type of chemical bond in that mixed carbon backbone. It’s “a kind of Achilles’ heel” for the material says Andy Pickford, a molecular biophysicist at the University of Portsmouth in the United Kingdom.

PETs have such a backbone — in this case, carbon interlaced with oxygen. Commonly found in textiles and soda bottles and accounting for roughly one-fifth of plastics created every year, PETs are a popular first target among biological recyclers and the closest to implementation at a commercial scale. The French firm Carbios, for example, plans to open a bio-recycling plant in northern France in 2025, with the aim of recycling 50,000 tons of PET waste annually.

The company is using a proprietary enzyme first identified in a pile of compost that researchers then modified to enhance its PET-bond-breaking ability and to withstand the higher temperatures at which the plastic becomes molten and soft. The enzyme can depolymerize 90 percent of PET in 10 hours, scientists from Carbios and its academic partner, the Toulouse Biotechnology Institute, reported in Nature in 2020.

Another startup, Australia-based Samsara Eco, plans to launch a similar 20,000-ton facility in Melbourne in 2024 that will also focus on PET.

Plastics include a variety of polymers, many of which are exceedingly hard to break down, thanks in part to strong bonds between their constituent atoms and their overall crystalline structure. Generally, it is easier to break down plastics into reusable subunits if the polymer backbone comprises carbon and some other atom, such as oxygen or nitrogen (bottom). Polymers with carbon-carbon backbones (top) remain extremely recalcitrant.

Plastics with a similar chemical makeup to PET, the polyamides and polyurethanes, are also promising targets for enzymatic recycling, as they are intrinsically susceptible to breakdown by enzymes, says Pickford, whose team at Portsmouth works on all three plastic types.

In addition to PET, Samsara now works on nylon, a type of synthetic polyamide commonly found in fabrics and textiles. In May, the firm announced a multiyear partnership with popular athletic brand Lululemon to produce “the world’s first infinitely recycled” nylon-polyester apparel from discarded clothes.

Researchers are also investigating polyurethanes, which comprise roughly 8 percent, or 25 million tons, of the global plastics pie and are common in foams such as furniture cushions and in diapers, sponges and sneakers. Various microbes can degrade some kinds of polyurethanes and Kers’ team at Birch Biosciences has zeroed in on some 50 different polyurethane-eating enzymes for testing, but the polymers are a structurally diverse group and will probably require diverse strategies.

Some tougher problems

While enzymatic recycling looks promising for plastics with mixed backbones, the outlook isn’t as rosy for those at the other end of the scale: plastics with backbones of pure carbon. This is an eclectic group that includes polyvinyl chloride (PVC), polyvinyl alcohol (PVA), polystyrene and polyethylene, which is used to make the ubiquitous plastic bag. Biological recycling of these plastics is far more challenging, says Pickford. “They’re kind of greasy, in a way, for enzymes. There’s not really much for an enzyme to grab hold of.”

Still, some scientists are working on these recalcitrant plastics — among them, Spain’s Bertocchini. “For some reason, I fixed on plastic bags, which are polyethylene-based,” she says. Also commonly used in food packaging film and takeout containers, polyethylene is by far the largest class of plastics manufactured today, accounting for more than 25 percent of the market. A decade on from their serendipitous discovery, Bertocchini and her team at Plasticentropy have identified the plastic-degrading enzymes in wax worm saliva — and have named them Demetra and Ceres. The enzymes degrade polyethylene within a matter of hours at room temperature by introducing oxygen into the carbon backbone.

Enzymes found in insects may hold the key for these tougher plastics. Microbiologist Chris Rinke at the University of Queensland in Australia, who works on polystyrene, commonly found in takeout food containers and disposable cutlery, is among the scientists looking at insect larvae, which have tough mouthparts that make them “very good at chewing through things” and breaking them down into smaller particles. “Then the microbes in the guts take it from there,” Rinke says.

Rinke came across the larva of a beetle called Zophobas morio — dubbed the Superworm — that breaks down polystyrene via a twofold process: mechanically shredding the plastic into smaller pieces, which “ages” it by introducing oxygen atoms, and then depolymerizing those bits using special bacterial gut enzymes that have yet to be identified.

But some experts are less optimistic about the outlook for biological recycling — especially for tackling plastics with harder-to-break backbones. “I’ve yet to be convinced that polyolefins like polyethylene and polypropylene and PVC will ever be realistic targets for enzymatic recycling at scale,” says Pickford. “There have been some interesting observations but converting those into an industrial process is going to be extremely difficult. I hope I’m wrong.”

There are hints of progress for PVC, but for now the brittle plastic, along with its cousins PVA and polylactic acid (PLA), remains largely unconquerable by enzymes. For such cases, it might be more feasible to shift toward creating new plastics that are recyclable, says Pickford.

Yet the findings keep coming: In 2020, a team from South Korea reported on a gut bacterium, Serratia fonticola, that conferred polystyrene-digesting abilities to the larvae of a black beetle called Plesiophthalmus davidis. Another group reported finding two cold-adapted fungal strains — Lachnellula and Neodevriesia, isolated from alpine soil and the Arctic shore, respectively — that could break down certain types of biodegradable plastic, including PLA.

Still, enzymes are only part of the battle. It’s unclear how easy it would be to scale up processes that harness these enzymes and what that scaled-up environmental footprint might look like.

“I think there’s never going to be one solution to all this,” says Vanessa Vongsouthi, head of protein engineering and research founder at Samsara Eco. “We have to work on advanced recycling, but in addition to that, policy, product redesign, reuse and even elimination … are all part of the bigger picture.”

Some policy changes are in the works. The United Nations is set to create the world’s first global plastic pollution treaty in 2024. It is aimed at curbing plastic pollution, and is expected to introduce new rules for production and the design of plastic products to make recycling easier, among other measures. And in the following year, laws mandating that 25 percent of the material in plastic containers and beverage bottles be recycled plastic will kick in in Washington, California and the European Union. But without additional changes and incentives, those efforts may be a drop in the bucket. As long as virgin plastic remains cheap due to the low price of fossil fuels, biological enzymes might not be able to compete.

“The main problem is cost,” says McGeehan. “Fossil-derived plastics are really cheap because they’re made at huge scale on a global market that’s very mature.” It also doesn’t help that some governments still incentivize producing plastics in this way, he says. “We need to really switch our thinking there and start incentivizing the PET or the other biodegradable processes in the way that the oil and gas industry benefited from in the past.”

McGeehan remains optimistic that once the technology for biological recycling improves, it will quickly become cost-efficient enough to compete with virgin plastic. Until then, researchers like Bertocchini will keep plugging away. She gave up her beloved beehives when she moved to Madrid in 2019, but today continues to expand her firm’s enzyme portfolio with moth and butterfly larvae. Enzymes will not solve the entire plastics problem, she says — “but this is a start.”

This article originally appeared in Knowable Magazine, a nonprofit publication dedicated to making scientific knowledge accessible to all. Sign up for Knowable Magazine’s newsletter.